Raviteja Kedarasetti, Ph.D., Senior Researcher II

Daniel Spring, Ph.D., Consulting Researcher II, Consulting Engineer II

In the complex world of pressure vessel design, nozzle connections represent one of the most critical structural discontinuities, creating zones of significant stress concentration that demand careful analytical consideration. These connections serve as the interface between pressure vessels and piping systems, subjecting the nozzle to a complex array of primary loads (such as internal pressure and dead weight) and secondary loads (including thermal expansion, seismic forces, and external piping reactions). The geometric transition from the cylindrical or spherical vessel wall to the nozzle opening creates inherent stress concentrations that can be several times higher than the nominal membrane stress in the vessel wall.

The accurate characterization of stress distributions around nozzle connections is paramount for several critical reasons. Safety considerations demand precise stress analysis to prevent catastrophic failures that could result in loss of containment, potential explosions, environmental contamination, and loss of life. Economic implications are equally significant as overly conservative design approaches lead to excessive material usage, increased manufacturing costs, unnecessarily stiff connections, and higher overall project expenditure while, conversely, insufficiently conservative methods can result in premature failure, costly unplanned shutdowns, extensive repair or replacement operations, and potential legal liabilities.

Whether the goal is to determine improved flexibilities for pipe stress analysis, calculate precise stress concentration factors for fatigue evaluation, or evaluate the adequacy of nozzle opening reinforcement, there is immense value in leveraging advanced numerical methods like finite element analysis (FEA). These methods enable engineers to simulate nozzle connections with unprecedented accuracy and reliability, providing insights that conventional design-by-rule approaches may miss.

Automating Design by Analysis: The Nozzle FEA Tool

While FEA is often the preferred approach for nozzle analysis, it comes with challenges. Model creation is time-intensive, particularly for complex geometries involving nozzle-to-shell connections. Nozzle connections require highly refined meshes at the junction, which increases model size and demands significant computational resources. Post-processing is equally intricate, requiring linearization of stresses, triaxiality evaluation, and other code-specific calculations. When optimizing a nozzle design, these challenges multiply, with each design iteration requiring model generation, analysis, and post-processing with consistent methodology.

Learn More About Equity Software’s New Nozzle FEA Tool

Equity Software®’s new Nozzle FEA tool addresses these challenges through automation and cloud computing, streamlining model generation, high-performance computing, and post-processing workflows. This innovative addition to our FEA suite leverages years of research and expertise in design by analysis at Equity, combined with proven software capabilities in creating cloud-native automated FEA solutions tailored for industrial asset design and evaluation.

The software automates FEA workflows to evaluate the structural integrity of nozzle attachments on pressure vessels, focusing specifically on cylindrical nozzles connected to cylindrical shells as well as spherical, torispherical, and ellipsoidal heads. By leveraging advanced computational methods, the software addresses the unique challenges associated with these complex geometries while providing engineers with essential tools to validate their designs against applicable code requirements. The tool automatically generates finite element models, executes analyses, and post-processes results to assess compliance with ASME Boiler and Pressure Vessel Code, Section VIII, Division 2 (ASME VIII-2). Details about the geometry, meshing, modeling and post-processing approach of the Nozzle FEA tool are discussed in Appendix A.

Comparative Analysis Methodology

This article leverages the Nozzle FEA tool to conduct a comprehensive comparison between design-by-rule and design-by-analysis approaches for evaluating nozzle connections. The study digs deeper into the design-by-analysis methodology by examining the differences between elastic and elastic-plastic stress analysis techniques. Additionally, elastic stress analysis results from the FEA tool are compared with the analytical solutions documented in WRC 297 to evaluate the relative merits and differences between these two computational approaches.

The comparative analysis encompasses 512 individual cases, systematically varying two critical geometric parameters: the nozzle-to-shell diameter ratio (d/D) and the diameter-to-thickness ratio of both the nozzle (d/t) and the shell (D/T). The range of parameters used in the calculation is shown in Table 1. This extensive parametric sweep enables identification of the limits and relative accuracy of each analytical method across the full spectrum of geometries commonly encountered in petrochemical applications. Such comprehensive coverage allows engineers to understand not just which method is most accurate but also under which geometric conditions each approach provides acceptable results. Nozzles on cylindrical shells with no offsets or angles were used for this comparative study.

| Parameter | Min Value | Max Value |

| Shell Inner Diameter | 25 in | |

| Shell Diameter-to-Thickness Ratio (D/T) | 12.5 | 100 |

| Nozzle-to-Shell Diameter Ratio (d/D) | 0.1 | 0.64 |

| Nozzle Diameter-to-Thickness Ratio (d/t) | 9 | 25 |

The material properties of SA106A at room temperature were used for all the calculations. We limited the loading to internal pressure only to keep the analysis simple. The appropriate pressure-thrust force was also included in the model. See Appendix A for details on the geometry, meshing, and boundary conditions.

The large-scale nature of this comparison study is made possible by the advanced automation and cloud-computing capabilities of the Nozzle FEA tool. Rapid model generation and automated post-processing eliminate the traditional bottlenecks associated with finite element analysis, while the scalable and highly optimized cloud deployment architecture enables thousands of calculations to be completed within a reasonable timeframe. This computational efficiency transforms what would traditionally be a long research endeavor spanning several months into a manageable analytical exercise. The combination of automation and computational scalability positions the Nozzle FEA tool as both a valuable resource for routine engineering analysis and an ideal research platform for generating insights into industry best practices. Detailed analysis run times for all cases will also be discussed, providing transparency into the computational efficiency achieved.

Establishing A Baseline: Comparisons with Physical Tests

Before applying any FEA tool to critical pressure vessel design decisions, rigorous validation against experimental data is essential to establish confidence in the numerical predictions. The accuracy of stress calculations, failure predictions, and design margins depends fundamentally on the model’s ability to replicate real-world structural behavior under operating conditions. To validate the Nozzle FEA tool, its burst pressure predictions are compared against physical test results documented in WRC 335, a comprehensive collection of experimental data for nozzle-to-vessel connections under ultimate loading conditions. This validation approach provides objective verification that the modeling methodology, element formulations, and material constitutive relationships accurately capture the complex failure mechanisms observed in physical tests.

Ten representative cases were selected from the comprehensive burst test database presented in WRC 335, chosen to span a wide range of nozzle-to-shell diameter ratios (d/D) and diameter-to-thickness ratios (d/t). All the tests were performed on nozzles on cylindrical shells. The complete shell and nozzle dimensional specifications for each test case are detailed in Table 1. The elastic-plastic stress analysis capability of the Nozzle FEA tool was employed to predict burst pressures for each validation case. The pressure increment beyond which numerical instability occurred and the model did not converge was assumed to be the FEA-predicted burst pressure.

A key challenge in this validation effort was the limited material information provided in WRC 335, which indicates only that the tested alloys are “like A106 B” without specifying the exact alloy composition or heat treatment methodology. To address this uncertainty, material properties were generated using A106 B as the baseline material from Equity’s comprehensive material database, with adjustments made using the tensile strength multiplier functionality in Equity Software’s MATDAT module. The tensile strength values used for the calculation are shown in Table 1. A tensile strength multiplier was calculated based on an A106 B tensile strength of 60,000 psi at room temperature.

| Test No. | Do (in.) | t (in.) | do (in.) | tn (in.) | Leg (in.) | SULT(psi) | WRC Bulletin 335 Burst Result (psi) | Nozzle FEA Burst Pressure (psi) | Abaqus FEA Burst Pressure (psi) |

| 1 | 12.750 | 0.375 | 6.625 | 0.280 | 0.313 | 67,650 | 3,800 | 3,494 | 3,490 |

| 2 | 12.750 | 0.375 | 7.445 | 0.690 | 0.375 | 67,650 | 4,100 | 3,921 | 3,840 |

| 8 | 18.000 | 0.375 | 4.000 | 0.188 | 0.250 | 54,755 | 2,310 | 2,127 | 2,125 |

| 10 | 18.000 | 0.375 | 4.000 | 0.375 | 0.375 | 54,755 | 2,370 | 2,337 | 2,275 |

| 13 | 18.000 | 0.375 | 6.000 | 0.250 | 0.250 | 54,755 | 2,120 | 2,074 | 2,110 |

| 14 | 18.000 | 0.375 | 6.000 | 0.375 | 0.375 | 54,755 | 2,260 | 2,256 | 2,230 |

| 16 | 8.625 | 0.322 | 4.500 | 0.237 | 0.250 | 59,307 | 4,650 | 3,967 | 3,960 |

| 21 | 24.000 | 0.312 | 4.500 | 0.237 | 0.250 | 79,340 | 1,970 | 1,903 | 1,860 |

| 22 | 24.000 | 0.312 | 12.750 | 0.250 | 0.250 | 84,275 | 1,580 | 1,815 | 1,845 |

| 29 | 4.500 | 0.237 | 2.380 | 0.154 | 0.188 | 60,437 | 6,175 | 5,666 | 5,595 |

Where FEA Makes a Difference – Design by Rule vs. Analysis

Equity conducted a comparative study of the maximum allowable working pressure (MAWP) predicted by the design-by-rule and design-by-analysis methodologies specified in ASME VIII-2. In the design-by-rule approach, the MAWP is determined separately for the parent shell and nozzle neck as well as from the nozzle reinforcement requirements. These calculations were performed using the NOZZLE module in PlantManager SAGE, which applies the codified equations and assumptions. For the design-by-analysis approach, an elastic-plastic stress analysis was performed using the Nozzle FEA tool. The plastic collapse (or burst pressure) was determined by incrementally ramping the internal pressure until the analysis failed to converge. The MAWP was then obtained by dividing the burst pressure at the last converged increment by the ASME design factor of 3.5.

The calculated MAWPs from the design-by-rule and design-by-analysis methods are compared in Figure 2 for both thin-walled nozzles (d/t = 9) and thick-walled nozzles (d/t = 25).

For thin nozzles (left plot), the discrepancy between the two methods is significant, particularly when the nozzle is attached to thicker shells (low D/T). In these cases, the design-by-rule method consistently predicts a lower MAWP than the FEA results, indicating an overly conservative outcome. As the shell becomes thinner (higher D/T), the predictions from the two approaches converge. The largest differences appear in large-diameter nozzles (d/D = 64%), where local reinforcement effects are not adequately captured by the simplified equations in the Code.

For thick nozzles (right plot), the agreement between the two methods improves considerably. The Code and FEA predictions follow a similar trend across nozzle diameters, with only modest discrepancies. Larger-diameter nozzles (e.g., 16-inch outer diameter) show cases where the Code again predicts slightly higher MAWP, but the divergence is far less pronounced than in the thin-nozzle configurations. This suggests that the additional wall thickness in the nozzle would almost always cause failure to occur in the shell, which is more in line with the simplifying assumptions in the Code equations.

A key insight from these results is that the conservatism of the design-by-rule method is not uniform. Its accuracy appears to hold within a narrow range of geometric parameters but deteriorates in thick-shell/thin-nozzle combinations, where it can produce overly conservative predictions. Conversely, in cases with thicker nozzles, the Code method can swing to the opposite extreme, yielding unconservative results. This variability is problematic because designers may assume the Code is always on the safe side when in fact it may either underpredict or overpredict the true capacity depending on geometry.

By contrast, the design-by-analysis approach using FEA provides consistent, physics-based results across the full parameter space. It explicitly accounts for local stress concentrations and load distribution that the design-by-rule equations cannot capture. These findings highlight the growing importance of advanced analysis tools. As automated FEA solutions such as Equity Software’s Nozzle FEA tool become more accessible, engineers are increasingly able to supplement or replace traditional analytical methods with more accurate, reliable predictions. This shift reduces the risks of both overdesign and unsafe underdesign, ultimately leading to more efficient and safer pressure vessel designs.

Diving Deeper into Design by Analysis – Plasticity

In this section, we compare the elastic and elastic-plastic stress analysis methods, as defined in Part 5 of ASME VIII-2. While elastic analysis remains a valid approach for a majority of designs, elastic-plastic analysis is strongly recommended for most applications due to its accuracy and reduced conservatism.

In an elastic analysis, linearized stresses are calculated and classified into categories such as membrane, bending, and peak stresses, which are then compared against allowable limits to evaluate design safety. This approach relies on stress linearization and classification procedures tailored to specific geometries and loading conditions. To calculate the MAWP using this method, we simply multiply the pressure applied to the model with the smallest design safety factor.

The elastic-plastic analysis method, on the other hand, simulates the material’s nonlinear behavior under load, directly evaluating the structure’s plastic collapse capacity. The allowable load is calculated by applying code-specified safety factors to the plastic collapse load, eliminating the need for stress categorization. This method is much more reliable because it accurately captures the redistribution of load due to material hardening when the stresses exceed the yield strength. Moreover, the complex geometry and loading conditions of a nozzle connection mean that the stress categorization requires significant knowledge and judgement, which is not universally agreed upon and is constantly evolving.

The results of the comparison between the MAWP from elastic and elastic-plastic stress analysis are shown in Figure 3. Overall, there is a good agreement between the two methods, and the elastic stress analysis is more conservative, as expected. However, for thick shells and thick nozzles (low d/t and D/T ratios), the elastic stress analysis can predict a higher MAWP than the elastic-plastic analysis. This indicates that relying solely on elastic analysis can lead to unconservative results, as it does not capture plastic collapse mechanisms that govern the true failure pressure. As the shell slenderness increases (higher D/), the predictions from elastic and elastic-plastic analyses converge. This trend suggests that for thinner shells, elastic analysis can be an acceptable approximation, but for thicker shells, it significantly overestimates capacity.

Traditionally, one of the major drawbacks of elastic-plastic stress analysis has been its computational cost. Compared to a purely elastic analysis, elastic-plastic simulations require iterative nonlinear solvers, finer load stepping, and more detailed convergence checks. As a result, they can take significantly longer to run, especially when set up manually on local hardware. However, with the automation and optimized cloud-computing infrastructure provided by Equity Software’s FEA suite of tools, the added complexity of elastic-plastic analysis no longer translates into additional burden for the user. From the user’s perspective, the workflow is identical to running an elastic analysis, and the model setup, job submission, and post-processing are all automated.

The difference between the elastic and elastic-plastic stress analyses lies in the solver runtime, which increases only modestly. As shown in Figure 4, the median runtime for an elastic stress analysis is approximately 2 minutes, while the corresponding elastic-plastic analysis requires around 10 minutes. Although this represents a fivefold increase, both runtimes are negligible compared to the days or even weeks of manual effort typically required for engineers to build finite element models, run analyses, and extract meaningful results without automation. In other words, what was once a prohibitive barrier to adopting elastic-plastic methods is now reduced to a matter of a few extra minutes in the cloud.

This computational efficiency is a critical enabler, and it allows engineers to adopt the more accurate elastic-plastic methodology in routine design work without compromising project timelines. By eliminating the historical trade-off between accuracy and effort, automated elastic-plastic analysis opens the door to safer, more reliable, and more efficient pressure vessel and nozzle designs.

Comparison with WRC 297

WRC 297 presents tabulated data in the form of plots that provide non-dimensional parameters (mr, nr, mθ, nθ). These parameters are used to calculate the components of stress in both the vessel and the nozzle, specifically at the nozzle-to-vessel junction. The bulletin also provides recommended limits on the geometric ratios to ensure the applicability of the method. Since the theoretical basis of WRC 297 is purely linear-elastic and does not account for nonlinearity or plastic effects, we compared its predictions against those from linear-elastic FEA to establish a consistent benchmark. The allowable stress margins from WRC 297 were calculated using Equity Software’s FAST2 module, and the MAWP was obtained by multiplying the minimum allowable stress margin by the applied pressure.

The results of this comparison are shown in Figure 5. Overall, the agreement between WRC 297 and elastic FEA is good, with WRC 297 generally yielding more conservative estimates of MAWP. For thinner shells and nozzles, the two methods are in close agreement, confirming that the simplified approach captures the key stress behavior in these geometries. However, as shell thickness increases, the discrepancy becomes more pronounced, with WRC 297 predicting significantly lower MAWP. The largest differences occur for thick, small-diameter nozzles, where the linear stress assumptions underlying shell theory break down and the simplified WRC approach cannot capture the true stress distribution.

This comparison highlights that while WRC 297 provides a reliable and conservative screening tool within its recommended geometric limits, elastic FEA offers a more accurate representation of nozzle stresses, particularly in cases where shell theory simplifications are invalid.

It is also important to note that this comparison was performed for a relatively straightforward nozzle configuration without hillside or angular offsets. In practice, such offsets are fairly common and introduce additional complexities in load transfer and stress concentration that WRC 297 is not equipped to address, whereas FEA can handle them directly. WRC 297 remains a useful and conservative screening tool within its recommended geometric limits and for simple nozzle geometries. However, for configurations involving thick shells, small-diameter nozzles, or geometric offsets, engineers should rely on elastic or elastic-plastic FEA to ensure accuracy and safety in design.

Discussion

The comparative analyses highlight the strengths and limitations of three commonly used approaches for nozzle design: design-by-rule (ASME VIII-2 Code equations), WRC 297, and design-by-analysis using FEA.

The design-by-rule approach provides a convenient, codified framework, but the results show that its accuracy is highly dependent on geometry. For thin shells and moderate nozzle sizes, the predictions are reasonably consistent with FEA. However, for thick shells combined with thin nozzles, the method becomes unreliable and sometimes overly conservative, but in other cases predicts higher allowable pressures than FEA, which is potentially unsafe. This inconsistency underscores that design-by-rule methods should be applied cautiously, as they rely on simplifying assumptions that are valid only within a narrow range of parameters.

The comparison of elastic vs. elastic-plastic FEA demonstrates the importance of considering nonlinear material behavior in nozzle assessments. Purely elastic analysis systematically overpredicts MAWP in stocky geometries (thick-walled shells with small-diameter nozzles), failing to capture stress redistribution and plastic collapse mechanisms. While elastic analysis may provide reasonable approximations for thinner shells and larger-diameter nozzles, it is not universally conservative. Elastic-plastic FEA, by contrast, offers a robust and physically accurate method across all geometries. With the availability of automated, cloud-based tools, the additional runtime for elastic-plastic analysis is minimal, making it practical for routine design. Elastic-plastic stress analysis also avoids the need for stress linearization post-processing procedures which may not produce valid linearized membrane and bending stresses under certain conditions. Moreover, ASME VIII-2 recommends the use of elastic-plastic stress analysis for components with complex geometries and loading conditions.

The WRC 297 comparison confirms its value as a conservative screening tool, especially for thin shells and simple nozzle configurations. Agreement with elastic FEA is very good in these cases. However, for thick shells or small-diameter nozzles, WRC 297 increasingly underestimates MAWP due to the breakdown of linear shell theory assumptions. Moreover, the method is limited to idealized geometries. In real-world applications, hillside or angular offsets are common, and these cannot be adequately addressed by WRC 297 but are naturally handled in FEA.

Taken together, these comparisons show a clear trend: simplified methods (design-by-rule and WRC 297) are useful for quick screening or within specific limits but cannot consistently guarantee accuracy across the full design space. By contrast, design by analysis using FEA, especially elastic-plastic analysis, provides consistent and reliable predictions regardless of geometry or loading conditions. The historical barrier of computational cost has largely been eliminated through automation and cloud computing, reducing analysis time from days or weeks to minutes.

Appendix A: Model Description

The Nozzle FEA tool employs a sophisticated finite element modeling approach designed to capture the complex stress states and structural behavior inherent in nozzle-to-vessel connections. This section details the geometric scope, element selection, meshing strategies, and boundary condition implementation that enable accurate design-by-analysis evaluations while maintaining computational efficiency.

Geometry and Scope

The Nozzle FEA program models cylindrical pressure vessels and their associated heads, which may be spherical, torispherical, or ellipsoidal in configuration. When simulating a nozzle attached to a head, the model incorporates a portion of the adjoining cylindrical shell to accurately represent boundary conditions and capture stress interactions within the critical transition region.

An optional reinforcement pad can be included around the nozzle on the pressure vessel shell with configurations supporting either constant diameter or constant width geometries surrounding the nozzle opening. All welds are explicitly modeled to ensure accurate representation of load transfer paths and force distribution. Nozzles may be specified in either set-in or set-on configurations, with options for uniform wall thickness or integrally reinforced (thickened) profiles.

Finite Element Discretization

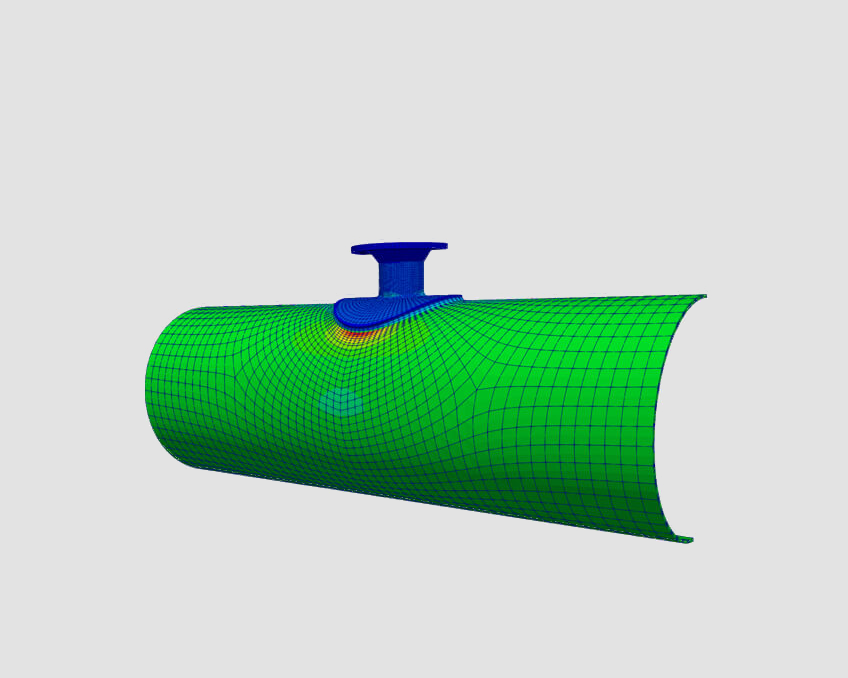

The model employs three-dimensional, 20-node quadratic hexahedral elements (C3D20R elements in Abaqus) for discretization. The selection of C3D20R elements provides optimal accuracy for evaluating stress concentrations and capturing nonlinear behavior around nozzle connections, which is essential for reliable design-by-analysis results.

Users maintain control over mesh density and the number of elements through the thickness of both shell and nozzle components. The meshing strategy employs a refined mesh near the nozzle connection, with consistent element sizing maintained throughout the reinforcement zone. Element size gradually increases with distance from this critical region to optimize computational efficiency while preserving accuracy where it matters most.

Sample meshes for nozzle connections on cylindrical, torispherical, and ellipsoidal shells are illustrated in Figure 6. Each weld leg is discretized using 2-4 elements, with the specific number determined by the weld size relative to the user-specified mesh density parameters. The model automatically generates separate node groups on internal and external surfaces within and outside the reinforcement zones to facilitate stress linearization calculations. An element-based surface is created on the component inner diameters for applying the pressure load.

Loads and Boundary Conditions

The free end of the flange attached to the nozzle is constrained using kinematic coupling to a central reference point, as shown in Figure 7. This coupling links translational degrees of freedom in the axial and circumferential directions while permitting radial expansion and contraction. The reference point serves as the application point for primary and secondary nozzle loads, including pressure thrust forces.

For nozzles on cylindrical shells, kinematic couplings are applied to both cylinder ends with corresponding reference nodes positioned at the geometric centers (Figure 7). These couplings link translational degrees of freedom in the axial and circumferential directions. One reference node is fully constrained, while shell loads including pressure thrust are applied to the reference node at the opposite end.

For nozzles on spherical, torispherical, or ellipsoidal heads, a kinematic coupling is applied at the open end of the cylindrical section connected to the head. This coupling links the translational degrees of freedom in the axial and circumferential directions while allowing radial expansion and contraction. The reference node at the center of the cylindrical shell is fully constrained.

Model Evaluation

The stress analysis can be performed using an elastic or elastic-plastic material model. The design is then evaluated for protection against plastic collapse using elastic or elastic-plastic stress analysis, as specified in Section 5.2 of ASME VIII-2. When an elastic-plastic stress analysis is performed, the program also evaluates the design for protection against local failure, as specified in Section 5.3. In this article, we are mostly concerned with the evaluation of protection against plastic collapse. For both elastic and elastic-plastic analysis, the material properties are gathered from Equity’s material database using the code of construction, the material specification, and the operating temperature.

In elastic stress analysis, stresses are calculated using FEA with the loads at design or operating conditions. Stress classification follows the procedure described in Annex 5-A of ASME VIII-2. Stress classification lines (SCLs) are drawn normal to the surface of the component. The stress tensors along each SCL are rotated to a local coordinate system aligned with the tangential, normal, and hoop directions. Membrane, bending, and peak stresses are then derived from these rotated tensors, and their equivalent stresses are compared to allowable limits.

In elastic-plastic stress analysis, the nonlinearities of the material with strain-hardening are included in the model. The loads are scaled by design factors based on the load combination and applied to the model in increments. The acceptance criterion for validating protection against plastic collapse is convergence (ability to achieve an equilibrium solution) of the FEA model for the combination of loads specified. The plastic collapse occurs when the loads cause overall structural instability of the nozzle connection, the shell, or the nozzle. This assessment provides confidence that the nozzle connection will not experience catastrophic failure due to overall structural instability under the design loading conditions. The elastic-plastic analysis captures the beneficial effects of material strain hardening and load redistribution that occur as localized yielding develops, providing a realistic assessment of the true structural capacity.

Please send any questions to the author by submitting the form below: