SIMFLEX-IV

Piping systems are designed to withstand a variety of external and internal stresses; however, any variation in mechanical or thermal loading, fluid flow, or weight may cause failure. With SIMFLEX-IV, you can proactively evaluate dynamic and static stresses to maintain integrity and code compliance across your entire piping system.

Download the SIMFLEX-IV overview here.

Static & Dynamic Piping Stress Analysis

SIMFLEX-IV is a cloud-based piping stress analysis software that will help you prevent potential failures by improving the structural integrity of piping systems and supporting structures. The intuitive once-through workflow calculates code compliance analysis, spring hanger design, rotating equipment load compliance reports, anchor and support load combination tables, and nozzle stresses, with or without friction, all in one run.

Read About the Effects of Friction on Rotating Equipment Compliance

-

Effects of Friction on Rotating Equipment Compliance: Modeling Considerations in Pipe Stress Simulation

Read More: Effects of Friction on Rotating Equipment Compliance: Modeling Considerations in Pipe Stress SimulationA recurring challenge is ensuring that modeling assumptions in pipe stress analysis don’t create hidden risks for rotating equipment and piping code compliance. This article explores how friction and vertical support behavior can dramatically influence nozzle load calculations, sometimes turning a compliant system into a non-compliant one. Using case studies and practical examples, the authors highlight best practices and advanced tools like SIMFLEX-IV to improve accuracy and reliability across complex operating conditions.

When to Use SIMFLEX-IV

SIMFLEX-IV integrates advanced static and dynamic piping stress analysis into your workflow, enabling the assessment of sustained, occasional, and displacement stresses at every data point throughout your piping system.

- Apply piping loads to critical components like rotating equipment, flanges, tank connections, etc.

- Automatic selection of spring hangers

- Prepare maximum anchor and restraint load tables based on various operating conditions

Enhanced Visualization Capabilities

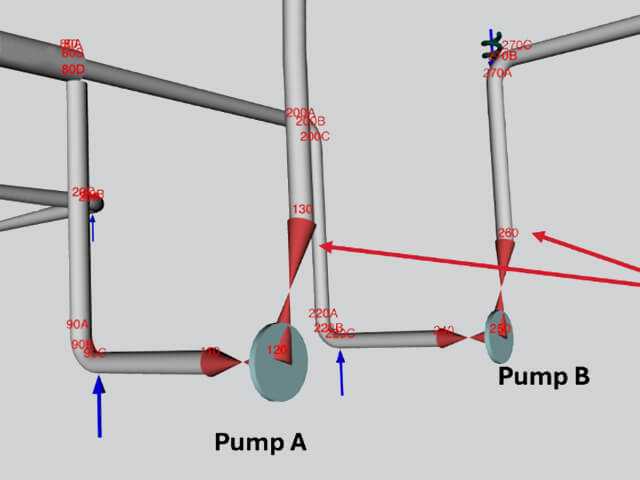

Leverage advanced 2D and 3D visualization tools to analyze calculation outcomes effectively.

- Streamline data entry by viewing all input data in a single window

- Utilize a 3D representation to verify the geometry of your piping systems

- Access comprehensive text results for straightforward and efficient reviews

- Observe deformations and stress contours throughout the entire piping system to analyze all load cases

Integrated B31.J Analysis Capabilities

ASME B31.J provides standardized flexibility and stress intensification factors (SIFs) for all piping components and branch connections.

- Fully integrated into SIMFLEX-IV for faster and easier analysis

- Automatically detect an unlimited number of SIF locations and flexibility factors

- Only a single keyword is needed to analyze any piping system to ASME B31.J

SIMFLEX-IV Key Features

SIMFLEX-IV enhances piping stress analysis, maximizing accuracy and efficiency through the following features:

- Standard piping-language input format based on industry terminology

- Extensive analysis capabilities for code compliance, spring design, rotating equipment load compliance, anchor & support load combination, and much more

- Adherence to the latest standards (ASME B31.1, B31.3, B31.4, B31.8, and B31.J).

- Automatic categorization of stresses for easier code requirement comparisons

- Comprehensive output reports with detailed piping system data and load case results

- Friction analysis with unlimited supports and multiple load cases

- Underground piping analysis with soil modeling and friction considerations

- Automated pressure vessel nozzle attachment analysis in accordance with WRC 107 and WRC 537